Category by style Corrugated Boxes

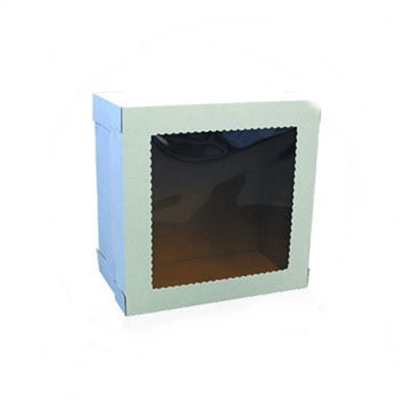

Window Corrugated Boxes PRODUCT CODE : 001125

Custom Window Corrugated Boxes made in any sizes, shapes, and designs. PYB offers quality packaging services with free shipping. Attractive wholesale boxes are a perfect match for your products.

What Are Custom Window Corrugated Boxes?

In the past, custom corrugated window boxes were employed mainly by manufacturers. To build custom boxes was quite a tedious process since it involved a lot of manual labor, and the initial cost to have a customized box would be the materials used. However, as manufacturing technology advanced, manufacturers started offering custom-made boxes at a much lower price. By the mid of the 1990s, many companies offered corrugated window boxes. Many manufacturers and businesses began to use these boxes for various purposes. These boxes are used to transport and deliver goods, furniture, and even services such as furniture delivery. They are also used to enclose packages in a bulk manner, and even to provide an insulated environment in which to protect fragile items that can be easily damaged by direct sunlight.

An advantage of having a custom window corrugated box is that it can enhance the design of a room, office, or building. A manufacturer who specializes in custom boxes can quickly produce a box that matches the color and style of a specific area. Since corrugated boxes can be formed according to specifications or designs, they are available in different sizes and shapes. If you are planning to make a design that you want for your building, you may find a wide variety of models on the internet. You may select a design that closely matches your needs, which can help you determine the size of your custom corrugated box, or you may customize your design so that it will look like a completely new creation.

Making your corrugated box will require that you purchase a few necessary materials, including metal sheeting, aluminum foil, adhesive sheets, plastic sheets, corrugated paper, glue, clips, hinges, nails, screws, and metallic wire. Once you have all of these materials ready, you will need to take into consideration several things to get the most out of your project. First, determine the thickness of the material that you are going to use. Some elements can easily bend when opened, and this can be quite dangerous. This is why it is essential to take note of the materials that you are using when purchasing them. Thick materials can hold their shape while folding and thus will not bend or move quickly.

Custom Window Corrugated Boxes at Printing Your Box

Another factor to consider in making a corrugated box is whether or not you are going to use a top or bottom panel for the custom window corrugated box. Some boxes are made with a lid and bottom, and others only feature a top. You should choose which type of box you prefer since there are advantages and disadvantages to each class. The importance of choosing a custom window box is evident. The use of custom corrugated boxes is becoming more popular with businesses and people alike.

Additional Info

- shipping

- DHL, FedEx, UPS, Ship Flat

- Turnaround

- Rush, 4-8 Business Days after Press-Ready

- Proof

- 3D Mock-up, Flat View, Free Sampling (On Demand)

- File Upload

- Send Artwork

- Additional Options

- Kraft, Biodegradable, Recycled Boxes

- Included Options

- Perforation, Die-Cut, Gluing

- Finishing

- Embossing, Foiling, Spot UV, Gloss UV, Matte UV, Gloss & Matte Lamination, Uncoated

- Colors

- CMYK, PMS CMYK +1PMS Color CMYK+2PMS Color, Plain Spot Color

- Paper Stock

- 10PT to 28PT – 60lb to 400lb Kraft, Cardboard and Corrugated

- Quantities

- Start from 100 Boxes

- Dimension

- (L+W+H) any custom sizes and shapes

- Key Features

- Custom sizes